Precision Turned Parts

We have the capacity to manufacture turned parts from 0.5mm to 65mm in diameter from bar and 300mm billet work using most engineering materials including brass, stainless steel, aluminium, alloys and plastics.

We have the capacity to manufacture turned parts from 0.5mm to 65mm in diameter from bar and 300mm billet work using most engineering materials including brass, stainless steel, aluminium, alloys and plastics.

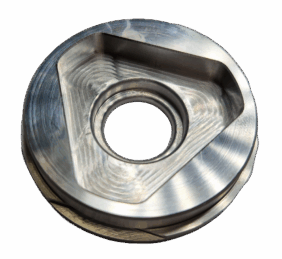

Full CNC machining and milling services for all your prismatic parts. Our dedicated vertical machining centres can produce large volumes of parts, in a wide variety of engineering materials, with short lead times.

We provide precision CNC machining of brass components, producing parts with tight tolerances, smooth finishes, and consistent quality for a variety of engineering and industrial applications.

We specialise in CNC machining stainless steel components with accuracy and tight tolerances, producing high-quality parts with superior surface finishes suitable for demanding applications.

High-quality aluminium turned parts engineered with precision. Lightweight, durable, and corrosion-resistant—ideal for aerospace, automotive, and medical industries. Crafted for strength, accuracy, and performance.

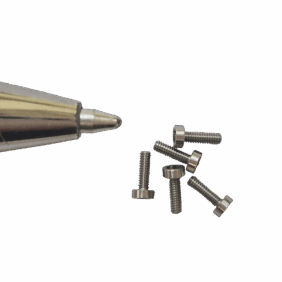

Precision-engineered micro turned parts, including small screws and intricate components, crafted with exceptional accuracy for demanding applications. Perfect for miniature assemblies where size, detail, and quality matter most.

Our CNC machining delivers high-precision plastic components, ensuring excellent surface finishes, consistent dimensions, and reliable performance for both technical and industrial uses.

We can supply machined parts with anodising, plating, polishing, coating, and heat treatments to enhance corrosion resistance, durability, and overall performance to your exact specifications.

At APT Leicester, we use state-of-the-art CNC turning technology to produce components that meet exact specifications, with every part manufactured to the AS9100 aerospace standard.

From intricate CNC turned components to large-scale production, our skilled team ensures precision, tight tolerances, and consistent quality in every project. Experience the APT Leicester difference, where engineering expertise meets innovative solutions.

We proudly supply precision-turned and milled components to a wide range of industries, including aerospace, medical, automotive, motorsport, security and industrial manufacturing. Every part we produce in Leicester is manufactured to the stringent AS9100 aerospace standard, ensuring consistent quality and reliability across all sectors.

Learn more about our CNC machining services and how we deliver precision turned parts to AS9100 standards.

“We have used APT Leicester for a number of years now, to produce a wide range of components that are shipped globally and we often receive positive comments upon the quality of the turned parts. This is down the great finish that the APT components always have, but maybe more importantly for myself apart from component quality, is that parts are always turned around and shipped both within the given time schedule and on budget.”

As we begin 2026, the team at APT Leicester would like to wish all our customers, suppliers, and partners a happy and successful New Year. We look forward to continuing to supply high-quality precision machined components and supporting new and ongoing projects throughout the year ahead.

Please note that APT Leicester will be closed for the Christmas period from 24th December to 5th January. During this time, our offices and production facilities will be shut, with normal service resuming on our return. We recommend planning orders and enquiries in advance to avoid any disruption over the holiday period.